BAND SAW MACHINES

Horizontal Swing Type Band Saw Machines are metal cutting machines that use a band saw blade to cut metals. The machine's design allows the saw blade to swing horizontally, enabling efficient cutting of various metal shapes and sizes.

Horizontal swing

design for easy loading/unloading.

Horizontal swing

design for easy loading/unloading.  Adjustable blade

tension and speed control.

Adjustable blade

tension and speed control.  Hydraulic or

pneumatic vice for secure material holding.

Hydraulic or

pneumatic vice for secure material holding. CNC or manual

control

systems.

CNC or manual

control

systems. High-precision

cutting with minimal kerf loss.

High-precision

cutting with minimal kerf loss. For More Details

please download our Catalogue.

For More Details

please download our Catalogue.

Specifications

| Specification | Value |

|---|---|

| Cutting Capacity | 250 & 230 x 230 MM |

| Blade Size | 3760 x 27 x 0.9 MM |

| Feed Length | 0 - 400 MM |

| Drive Motor | 3 HP |

| Hydraulic Motor | 1 HP |

| Coolant | 0.15 HP |

| Machine Operations | Hydraulic |

| Cutting Speed | 22, 44, 66, 88 m/min (4 Step SPZ Pulley) |

| Variable Speed | 20-100 m/min by VFD, Optional |

| Band Tension | Manual |

| Overall Size (L x W x H) | 1975 x 1950 x 1730 MM |

| Machine Weight | 950 Kg |

| Bundle Cutting Size (Optional Equipment) | 110 - 150 W x 60 - 100 H MM |

BAND SAW MACHINES

The machine has a capacity to cut upto 250 diameter is distinguished by its robust and compact construction and its capability to cut a wide range of materials with maximum productivity. It is designed for use of Bi-metal bandsaws.

It is suitable

for

cutting bars in bundles, tubes and different profiles.

It is suitable

for

cutting bars in bundles, tubes and different profiles.  Length of cut be

mechanical counter within 0.1 MM and upto a maximium of 400 MM

in single stroke.

Length of cut be

mechanical counter within 0.1 MM and upto a maximium of 400 MM

in single stroke.  Number of pieces

to

be cut can be prograMMed and machine will stop after

prograMMed number of pieces are cut.

Number of pieces

to

be cut can be prograMMed and machine will stop after

prograMMed number of pieces are cut.  For longer

cutting

lengths multi-indexing upto 9 x 400 i.e., 3600MM is feasible.

For longer

cutting

lengths multi-indexing upto 9 x 400 i.e., 3600MM is feasible.

Specifications

| Specification | Value |

|---|---|

| Cutting Capacity | 300 x 175 MM / 250 x 250 MM |

| Blade Size | 3505 x 34 x 1.1 MM |

| Blade Speed | 20, 40, 60, 80 m/min (Step) VFD Drive |

| Blade Tension | Spring Loaded (manual) / Hydraulic band Tension |

| Shuttle Feed | Single Stroke: 400 MM / Multiple Stroke: 9 x 400 MM |

| Work Table Height | 700 MM |

| Motors | Blade Drive: 250 MM / Hydraulic: 200 x 175 MM / Coolant: 250 x 250 MM |

| Machine Weight | 1250 kg |

| Floor Area (LxBxH) | 1975 x 1880 x 1740 MM |

BAND SAW MACHINES

The HBM 300 NC series band saw machine is a high-performance tool designed for precise metal cutting in various industrial applications. Featuring advanced NC control technology, this machine allows for automated and accurate adjustments, enhancing operational efficiency and reducing the likelihood of human error.

Built for

heavy-duty

use, the robust design ensures long-term reliability and reduced downtime.

Built for

heavy-duty

use, the robust design ensures long-term reliability and reduced downtime.

Intuitive

controls

simplify setup and operation, making it accessible for operators of varying

skill levels.

Intuitive

controls

simplify setup and operation, making it accessible for operators of varying

skill levels. The combination

of

efficiency, durability, and reduced waste translates to lower operational

costs

over time.

The combination

of

efficiency, durability, and reduced waste translates to lower operational

costs

over time. The NC control

system

enables accurate adjustments, ensuring high-quality cuts and reducing waste.

The NC control

system

enables accurate adjustments, ensuring high-quality cuts and reducing waste.

Specifications

| Specification | Value |

|---|---|

| Cutting Capacity | 300 x 175 MM / 250 x 250 MM |

| Blade Size | 3505 x 34 x 1.1 MM |

| Blade Speed | 20, 40, 60, 80 m/min (Step) VFD Drive |

| Blade Tension | Spring Loaded (manual) / Hydraulic band Tension |

| Shuttle Feed | Single Stroke: 400 MM / Multiple Stroke: 9 x 400 MM |

| Work Table Height | 700 MM |

| Motors | Blade Drive: 250 MM / Hydraulic: 200 x 175 MM / Coolant: 250 x 250 MM |

| Machine Weight | 1250 kg |

| Floor Area (LxBxH) | 1975 x 1880 x 1740 MM |

Kolchen is a renowned German manufacturer of high-quality band saw blades for metal cutting applications.

Kolchen Band Saw Blade

This bi-metal band saw blade is an excellent choice for a wide range of cutting applications. It's made from high-quality steel combined with special breaking steel, which gives it superior strength and durability.

An Excellent

general

Purpose Bi-metal Band Saw Blade made with high quality steel

combined with special breaking steel which is an all.

An Excellent

general

Purpose Bi-metal Band Saw Blade made with high quality steel

combined with special breaking steel which is an all. Carbon

Steel,Alloy

Steel,Aluminium, Mild Steel,Cast Iron, Aluminium Casting , etc.,

Carbon

Steel,Alloy

Steel,Aluminium, Mild Steel,Cast Iron, Aluminium Casting , etc.,

Benefits :

Applications :

Specifications

| Width x Thickness | TPI | 2/3 | 3 | 3/4 | 4 | 4/6 | 5/8 | 6 | 6/10 | 8/12 | 10/14 | 14/18 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 19 x 0.9 MM ¾ x 0.035 INCHES |

* | * | * | * | * | * | * | * | ||||

| 27 x 0.9 MM 1 x 0.035 INCHES |

* | * | * | * | ||||||||

| 34 x 1.1 MM 1 - 1/4 x 0.042 INCHES |

* | * | * | * | * | * | ||||||

| 41 x 1.3 MM 1 - ½ x 0.050 INCHES |

* | * | * | * |

Kolchen Band Saw Blade

This bi-metal band saw blade offers long blade life and extreme durability, with a customized tooth profile that resists strip page even at high feed rates. The blade features a special design to reduce chipping and enhance life, resulting in faster cutting and deep penetration. It's suitable for cutting mild, carbon, tool, stainless steel, and metals up to 40 HRC. Overall, this blade is a reliable investment for anyone who values performance and precision in their cutting tools.

Long Blade life

and

extreme durability customized tooth profile that resists tooth strip page

even

at high feed rates

Long Blade life

and

extreme durability customized tooth profile that resists tooth strip page

even

at high feed rates Mild Steel,

Carbon

Steel,Tool Steel,Stainless Steel and Hardness upto 40 HRC

Mild Steel,

Carbon

Steel,Tool Steel,Stainless Steel and Hardness upto 40 HRC

Benefits :

Applications :

Specifications

| Width x Thickness | TPI | 2/3 | 3/4 | 4/6 | 5/7 | 8/11 | 12/6 |

|---|---|---|---|---|---|---|---|

| 19 x 0.9 MM 3/4 x 0.35 INCHES |

* | * | * | ||||

| 27 x 0.9 MM 1 x 0.35 in |

* | * | * | * | * | ||

| 34 x 1.1 MM 1 - 1/4 x 0.42 INCHES |

* | * | * | * | |||

| 41 x 1.3 MM 1 - 1/2 x 0.50 INCHES |

* | * | * | * | |||

| 54 x 1.6 MM 2 x 0.63 INCHES |

* | * | * | ||||

| 67 x 1.6 MM 2 - 5/8 x 0.63 INCHES |

* | * |

Kolchen Band Saw Blade

. This versatile bi-metal band saw blade is designed for different cutting applications and materials. It features a special powder metallurgy high-speed steel cutting edge, variable pitch with positive rake angle, and optimized surface treatment. It's suitable for cutting mild steel, carbon steel, tool steel, stainless steel, and metals up to 40 HRC.

The Blade is

designed

to meet different application on various type of Cutting Materials

The Blade is

designed

to meet different application on various type of Cutting Materials Mild Steel ,

Carbon

Steel , Tool Steel , Stainless Steel and hardness upto 40 HRC

Mild Steel ,

Carbon

Steel , Tool Steel , Stainless Steel and hardness upto 40 HRC

Benefits :

Applications :

Specifications

| Width x Thickness | TPI | 1.0 / 1.5 | 1.4 / 2.0 | 2/3 | 3/4 | 4/6 | 5/8 |

|---|---|---|---|---|---|---|---|

| 27 x 0.9 MM 1 x 0.035 in |

* | * | * | ||||

| 34 x 1.1 MM 1 – 1/4 x 0.042 in |

* | * | * | ||||

| 41 x 1.3 MM 1 – 1/4 x 0.050 in |

* | * | * | ||||

| 54 x 1.6 MM 2 x 0.63 in |

* | * | * | * | * | ||

| 67 x 1.6 MM 1 – 5/8 x 0.063 in |

* | * | * | * |

Kolchen Band Saw Blade

This bi-metal band saw blade is designed for high performance on difficult-to-cut materials. It's made from powder metallurgy high-speed steel with a hard cutting edge, and is suitable for cutting solid and bars of various materials, including die steel, alloy steel, bearing steel, aluminum alloy, tool steel, and stainless steel.

Designed for high

performance on difficult to cut material

Designed for high

performance on difficult to cut material Suitable for

large

selection for solid and bars of die steel, Alloy Steel, Bearing

Steel, Aluminium Alloy, Tool Steel and Stainless Steel

Suitable for

large

selection for solid and bars of die steel, Alloy Steel, Bearing

Steel, Aluminium Alloy, Tool Steel and Stainless Steel

Benefits :

Applications :

Specifications

| Width x Thickness | TPI | 1.0 / 1.5 | 1.4 / 2.0 | 2/3 | 3/4 | 4/6 | 5/8 |

|---|---|---|---|---|---|---|---|

| 27 x 0.9 MM 1 x 0.035 in |

* | * | * | ||||

| 34 x 1.1 MM 1 – 1/4 x 0.042 in |

* | * | * | ||||

| 41 x 1.3 MM 1 – 1/4 x 0.050 in |

* | * | * | ||||

| 54 x 1.6 MM 2 x 0.63 in |

* | * | * | * | * | ||

| 67 x 1.6 MM 1 – 5/8 x 0.063 in |

* | * | * | * |

Kolchen Band Saw Blade

This bi-metal band saw blade features a specially designed high-low profile for easier penetration and reduced cutting forces. It's made from powder metallurgy high-speed steel with a premium breaking material for optimum fatigue life, and has a tooth height difference and special set design for smooth cutting. It's suitable for cutting medium to large size solid materials, as well as difficult-to-cut materials with higher feed rates.

Specially

designed

high – low profile for easier penetration of material and reduced Cutting

Forces

Specially

designed

high – low profile for easier penetration of material and reduced Cutting

Forces

Medium to large

Size

Solid Materials, Higher Feed Rate for difficult to Cut

Materials

Medium to large

Size

Solid Materials, Higher Feed Rate for difficult to Cut

Materials

Benefits :

Applications :

Specifications

| Width x Thickness | TPI | 0.75 / 1.25 | 1.0 / 1.5 | 1.4 / 2.0 | 2/3 | 3/4 | 4/6 |

|---|---|---|---|---|---|---|---|

| 27 x 0.9 MM 1 x 0.35 in |

* | * | * | ||||

| 34 x 1.1 MM 1 – 1/4 x 0.42 in |

* | * | * | ||||

| 41 x 1.3 MM 1 - 1/2 x 0.50 in |

* | * | * | ||||

| 54 x 1.6 MM 2 x 0.63 in |

* | * | * | * | * | ||

| 67 x 1.6 MM 2 – 5/8 x 0.63 in |

* | * | * | * | * | ||

| 80 x 1.6 MM 3 x 0.063 in |

* |

Kolchen Band Saw Blade

This Multi Chip Set Style Carbide tipped Blade features a specially designed for Multipurpose geometry to cut a wide range of Materials

MultiChip Set

Style

Carbide Tipped Band Saw Balde is specially designed to cut a

wide range of materials with multipurpose geometry.

MultiChip Set

Style

Carbide Tipped Band Saw Balde is specially designed to cut a

wide range of materials with multipurpose geometry.

Aerospace Alloys

,

Bearing Steel , Nickel Based Alloys , Tool Steel , Die Steel

and Titanium alloys

Aerospace Alloys

,

Bearing Steel , Nickel Based Alloys , Tool Steel , Die Steel

and Titanium alloys

Benefits :

Applications :

Specifications

| Width x Thickness | TPI | 0.75 / 1.0 | 1.0 / 1.25 | 1.4 / 2.0 | 2/3 | 3/4 |

|---|---|---|---|---|---|---|

| 27 x 0.9 mm 1 x 0.35 in |

* | * | ||||

| 34 x 1.1 mm 1 – 1/4 x 0.42 in |

* | * | ||||

| 41 x 1.3 mm 1 - 1/2 x 0.52 in |

* | * | ||||

| 54 x 1.6 mm 2 x 0.63 in |

* | * | * | * | ||

| 67 x 1.6 mm 2 – 5/8 x 0.63 in |

* | * | * | * | ||

| 80 x 1.6 mm 3 x 0.063 in |

* | * |

Tenryu Saw Blades

Tenryu circular saw blades are synonymous with precision and durability, setting a benchmark in the cutting tools industry. Renowned for their superior craftsmanship, these blades are engineered to deliver flawless cuts with minimal effort.

Tenryu saw blades are engineered with advanced technology to provide clean, precise cuts.

Their design minimizes splintering and ensures smooth finishes, making them ideal for both professional and DIY applications.

Tenryu saw blades are engineered with advanced technology to provide clean, precise cuts.

Their design minimizes splintering and ensures smooth finishes, making them ideal for both professional and DIY applications.

Designed with vibration-dampening features, Tenryu blades ensure stable operation, reducing noise and operator fatigue during prolonged use.

Designed with vibration-dampening features, Tenryu blades ensure stable operation, reducing noise and operator fatigue during prolonged use.

These blades cater to various materials such as wood, metal, plastic, and composite materials,

making them versatile tools for construction, carpentry, and metalworking.

These blades cater to various materials such as wood, metal, plastic, and composite materials,

making them versatile tools for construction, carpentry, and metalworking. With sharp, precision-ground teeth and optimized blade geometry, they enable faster cutting with less effort, improving workflow efficiency.

With sharp, precision-ground teeth and optimized blade geometry, they enable faster cutting with less effort, improving workflow efficiency.

Benefits :

Specifications

| Category | Details |

|---|---|

| Features | Despite its thin kerf, this model boasts longevity, perpendicularity, and smooth cut surface. |

| Materials | Bar steel, Stainless steel bar, Solid-drawn pipe |

| Shapes of Materials | Solid materials, Pipe, Other various shaped materials |

| Blade Dimensions |

|

| Tooth Geometry | Notched tooth with breaker |

| Tooth Material | Carbide P30, Cermet, PVD Coating (TIN, AITIN, CrN) |

SYNERGY Metal Cutting Machine

The SYNERGY Metal Cutting Machine is likely designed for precision metalworking tasks, such as cutting, shaping, or fabricating various metal materials. These machines can vary in terms of technology (like laser, plasma, or water jet cutting), features, and specifications.

Enhanced Bi Metal

Blade Life

Enhanced Bi Metal

Blade Life

Hardened and

Grounded Worm Gear providing Longer service Time.

Hardened and

Grounded Worm Gear providing Longer service Time. All Tapered

Bearing

Gear Box.

All Tapered

Bearing

Gear Box. Efficicient Self

Centering Vice for Job Clamping

Efficicient Self

Centering Vice for Job Clamping Separate Chip

Collection Tray for Easy Removal of Chips

Separate Chip

Collection Tray for Easy Removal of Chips Three Stepped

Pulley

to have three different Speed Spectrums as per material Chosen

Three Stepped

Pulley

to have three different Speed Spectrums as per material Chosen Hydro Mechancial

Guided Down Feed System to provide Precise down Feed and Pressure while

cutting

Hydro Mechancial

Guided Down Feed System to provide Precise down Feed and Pressure while

cutting Carbide wear Pad

and

Bearign Guide Balde which provides accurate Cutting.

Carbide wear Pad

and

Bearign Guide Balde which provides accurate Cutting. Fully Supported

Machine Body giving no vibrations, which mimimizes the Blade tooth

breakage.

Fully Supported

Machine Body giving no vibrations, which mimimizes the Blade tooth

breakage. Integrated

Cooling

System

Integrated

Cooling

System Automatic Power

cut

after each Cut

Automatic Power

cut

after each Cut Adjustable Job

Stopper

Adjustable Job

Stopper Econoimical Power

Consumption

Econoimical Power

Consumption

Benefits :

Technical Specifications

| MODEL | UNIT | S - Pro 200 | S - Pro 250 | S - Pro 300 | S - Pro 350 | S - Pro 400 |

|---|---|---|---|---|---|---|

| Capacity | mm | 200 | 250 | 300 | 350 | 400 |

| Blade Dimension | mm | 3000 * 27 * 0.9 | 3200 * 27 * 0.9 | 3760 * 27 * 0.9 | 4100 * 27 * 0.9 | 4400 * 34 * 0.9 |

| Motor Drive | HP / Volt / RPM | 1 / 415 / 1440 | 1 / 415 / 1440 | 1 / 415 / 1000 | 1 / 415 / 1000 | 1 / 415 / 1000 |

| Coolant Pump | HP / Volt / Lit per Minute | 0.15 / 415 / 42 | 0.15 / 415 / 42 | 0.15 / 415 / 42 | 0.15 / 415 / 42 | 0.15 / 415 / 42 |

| Blade Speed | Meter / minute | 20 - 75 | 20 - 75 | 20 - 75 | 20 - 75 | 20 - 75 |

| Machine Dimension | mm | 1650 * 650 * 900 | 1700 * 680 * 920 | 2400 * 830 * 1100 | 2580 * 830 * 1050 | 2680 * 850 * 1250 |

| Approx. Weight | Kg. +/- 20 | 325 | 340 | 750 | 805 | 890 |

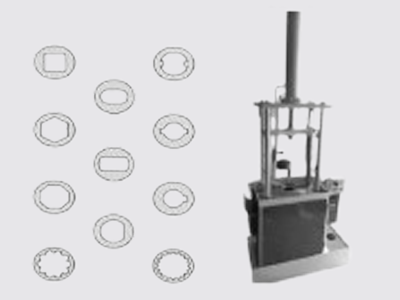

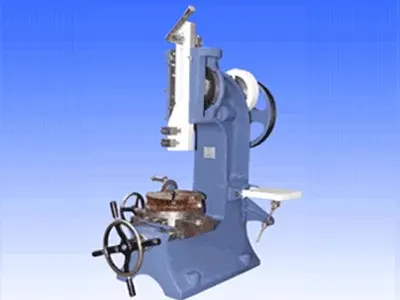

Keyway Machines

A semi-automatic keyway milling machine is a specialized tool designed to efficiently create keyways—slots essential for securing components like gears and pulleys onto shafts. This machine operates with minimal manual intervention, enhancing productivity while ensuring precision in cutting.

High accuracy,

P9

tolerance can be achieved.

High accuracy,

P9

tolerance can be achieved. Reliable,

Economical

& Durable

Reliable,

Economical

& Durable Accurate depth

control by means of its accurate mechanism

Accurate depth

control by means of its accurate mechanism Automatic

operation

to get 100% desired output.

Automatic

operation

to get 100% desired output. Easy to operate,

can

be handled by semi skilled operator

Easy to operate,

can

be handled by semi skilled operator More tooling life

More tooling life

No additional

accessories required.

No additional

accessories required. All components

made

to close tolerance.

All components

made

to close tolerance. Rugged

construction,

long service life.

Rugged

construction,

long service life.

Key Features :

Technical Specifications

| Specification | Model 1 | Model 2 |

|---|---|---|

| Spindle RPM | 1-150 1800 RPM |

1-200 0 - 2200 RPM |

| Length of Key-Way | 5 mm to 150 mm | 5 mm to 200 mm |

| Shaft Clamping Dia | 12 mm to 70 mm | 12 mm to 100 mm |

| Key-Way Size | 3 mm to 13 mm | 3 mm to 16 mm |

| Standard Collet | ER - 20 | ER - 25 |

| Power Required | 1 HP / 0.75 KW | 1.5 HP / 1.12 KW |

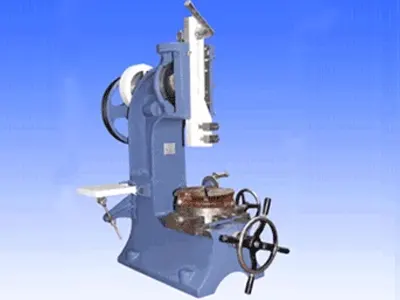

Keyway Machines

A fully automatic keyway milling machine is a state-of-the-art piece of equipment designed to efficiently create precise keyways in various materials, such as metals and alloys. This machine operates autonomously, utilizing advanced computer numerical control (CNC) technology to execute complex milling tasks with high precision and speed.

Table travel

mechanism with LM guide ways and Ground Ball Screw.

Table travel

mechanism with LM guide ways and Ground Ball Screw. Table and

Spindle

both feed travel by servo motor and controlled by plc.

Table and

Spindle

both feed travel by servo motor and controlled by plc. Color HMI for

Program and Data entry.

Color HMI for

Program and Data entry. Supports

Multiple

key ways and drilling operation.

Supports

Multiple

key ways and drilling operation. At a single time

either key way or drilling operation can possible.

At a single time

either key way or drilling operation can possible. Only single tool

can

clamp at a one time.

Only single tool

can

clamp at a one time. Number of

program

can be saved as per part name or number.

Number of

program

can be saved as per part name or number. Automatic

Motorized

lubrication system.

Automatic

Motorized

lubrication system. Self centering

vice

provided with machine.

Self centering

vice

provided with machine. Heavy

construction

of machine base and body.

Heavy

construction

of machine base and body.

Key Features :

Technical Specifications - IFA-275

| Specification | IFA-275 |

|---|---|

| Spindle RPM | 0-3700 RPM |

| Shaft Clamping Dia | 12 mm to 100 mm |

| Length Of Key Way | 5 mm to 275 mm |

| Key Way Size | 3 mm to 16 mm |

| Max Drilling Capacity | 8 mm x 40 mm depth |

| Standard Collet | ER-25 |

| Power Required | 2.5 HP / 1.86 KW |

Broaching Machines

A hydraulic horizontal pull-type broaching machine is designed for efficient and precise machining of internal and external profiles in various materials. This machine utilizes hydraulic power to drive the broach, allowing for a strong and consistent cutting force that enhances productivity.

Table travel

mechanism with LM guide ways and Ground Ball Screw.

Table travel

mechanism with LM guide ways and Ground Ball Screw. Utilizes

hydraulic

power to drive the broach, providing

consistent cutting force and enabling efficient material removal.

Utilizes

hydraulic

power to drive the broach, providing

consistent cutting force and enabling efficient material removal. The horizontal

setup

allows for easier handling of larger

workpieces and better accessibility during setup and operation.

The horizontal

setup

allows for easier handling of larger

workpieces and better accessibility during setup and operation. The broach is

pulled

through the material, which can enhance

cutting efficiency and extend tool life by reducing wear.

The broach is

pulled

through the material, which can enhance

cutting efficiency and extend tool life by reducing wear. Capable of

performing various broaching operations, including

internal keyways, splines, and gears, on different materials.

Capable of

performing various broaching operations, including

internal keyways, splines, and gears, on different materials. Operators can

often

adjust the stroke length to

accommodate different workpiece sizes and profiles, adding flexibility to

the

machine.

Operators can

often

adjust the stroke length to

accommodate different workpiece sizes and profiles, adding flexibility to

the

machine. Designed for

high

accuracy, these machines ensure that

each broached feature is consistent across multiple parts.

Designed for

high

accuracy, these machines ensure that

each broached feature is consistent across multiple parts. Typically

equipped

with intuitive controls that allow for

easy operation and monitoring during the broaching process.

Typically

equipped

with intuitive controls that allow for

easy operation and monitoring during the broaching process. Includes safety

guards, emergency stop buttons, and other measures

to protect operators during operation.

Includes safety

guards, emergency stop buttons, and other measures

to protect operators during operation.

Key Features :

Technical Specifications - IB Models

| Specification | IB-1050 | IB-1250-H5 | IB-1250-H6-24 |

|---|---|---|---|

| Stroke Length | 1050 mm | 1250 mm | 1250 mm |

| Power Pack | 5 HP | 5 HP | 7.5 HP |

| Ton Capacity | 5 TON | 5 TON | 11 TON |

| Max Job Clamping Dia | 400 mm | 400 mm | 600 mm |

| Job Plate | 250 mm | 250 mm | 250 mm |

Broaching Machines

A vertical broaching push type machine is a specialized tool used in manufacturing to shape or finish materials through a linear cutting action. This machine employs a vertically oriented broach, which is pushed through the workpiece to create specific profiles, holes, or shapes with high precision.

Table travel

mechanism with LM guide ways and Ground Ball Screw.

Table travel

mechanism with LM guide ways and Ground Ball Screw. Vertical orientation

allows for easy loading and unloading of workpieces.

Vertical orientation

allows for easy loading and unloading of workpieces. Utilizes a push

mechanism where the broach is driven through the material, ideal for deep cuts

and intricate shapes.

Utilizes a push

mechanism where the broach is driven through the material, ideal for deep cuts

and intricate shapes. Achieves high

dimensional accuracy and surface finish.

Achieves high

dimensional accuracy and surface finish. Effective for a wide

range of materials, including metals and plastics.

Effective for a wide

range of materials, including metals and plastics. Commonly used in

automotive, aerospace, and manufacturing industries for parts like gears,

keyways, and slots.

Commonly used in

automotive, aerospace, and manufacturing industries for parts like gears,

keyways, and slots. Reduces machining

time compared to traditional methods, increasing overall productivity.

Reduces machining

time compared to traditional methods, increasing overall productivity. Requires regular

maintenance to ensure the longevity of the broach and machine components.

Requires regular

maintenance to ensure the longevity of the broach and machine components.

Key Features :

Technical Specifications

| Specification | Details |

|---|---|

| Type | Vertical Broaching Push |

| Grade | Automatic |

| Brand | Hardik Industries |

| Power Consumption | 5 HP |

| Machine Capacity | 5 to 6 Ton |

| Power Options | 3 HP / 5 HP |

| Weight | 700 kg |

| Stroke Length | 650 mm |

| Condition | New |

Broaching Machines

A vertical broaching machine with a ratriever system is an advanced machining tool designed for efficient and precise broaching operations. This type of machine features a ratriever mechanism, which automates the retrieval of the broach after the cutting process, significantly enhancing productivity and reducing manual handling.

The vertical setup facilitates easy access to

the workpiece, streamlining the loading and unloading process

The vertical setup facilitates easy access to

the workpiece, streamlining the loading and unloading process Automates the removal of the broach post-operation, minimizing downtime and improving workflow efficiency.

Automates the removal of the broach post-operation, minimizing downtime and improving workflow efficiency. Delivers high accuracy in creating complex shapes, keyways, and profiles in various materials.

Delivers high accuracy in creating complex shapes, keyways, and profiles in various materials. The automated retrieval system speeds up the overall production cycle, making it suitable for high-volume applications.

The automated retrieval system speeds up the overall production cycle, making it suitable for high-volume applications. Capable of broaching a variety of materials, including metals, plastics, and composites, for diverse industrial applications.

Capable of broaching a variety of materials, including metals, plastics, and composites, for diverse industrial applications. Often includes safety mechanisms to protect operators during the broaching and retrieval processes.

Often includes safety mechanisms to protect operators during the broaching and retrieval processes. Designed for durability with lower maintenance needs, ensuring consistent performance over time.

Designed for durability with lower maintenance needs, ensuring consistent performance over time.

Key Features :

Technical Specifications

| Description | Capacity | 10 to 12 Ton | 14 to 15 Ton | |

| Maximum Stroke | M.M | 1500 mm | 1500 mm | |

| Cutting Speed | M/Min | 1-6 | 1-6 | |

| Return Speed | M/Min | 14/15 | 18/19 | |

| Hole Die | MM | 90/100 | 90/100 | |

| Main Motor | HP | 10 | 15 | |

| Coolant Motor | HP | 0.25 | 0.25 | |

| Broach Lifter Stroke | MM | 600/800 | 600/800 |

Broaching Machines

The PCT Make Vertical Broaching Machine is a precision-engineered solution designed for high-accuracy and high-efficiency broaching applications. This machine is ideal for industries requiring smooth and precise internal or external shaping of metal components.

Centering & Facing Machines

It accurately locates the center of a workpiece, which is crucial for subsequent machining operations. This ensures that all cuts and features are symmetrical and correctly aligned.This process involves machining the flat surfaces of a workpiece, providing a smooth finish and ensuring that parts fit together correctly. The machine can remove material from the face of the workpiece to achieve the desired dimensions and surface quality.

Rugged and

predsion

ground cast iron bed

Rugged and

predsion

ground cast iron bed Ground and

scraped

milling slides.

Ground and

scraped

milling slides. Spindle with

taper

roller bearings.

Spindle with

taper

roller bearings. Hydraulic

operated,

hard crome plated quill type spindle.

Hydraulic

operated,

hard crome plated quill type spindle. Through spindle

coolant.

Through spindle

coolant. Linear guide

mounted

spindle motors.

Linear guide

mounted

spindle motors. Self centering

vice

with Hardened and ground work holding vee blocks.

Self centering

vice

with Hardened and ground work holding vee blocks. Hardened and

ground

tool holder provided with carbide cutter insert type tools.

Hardened and

ground

tool holder provided with carbide cutter insert type tools. All machine

setting

elements are at operator side.

All machine

setting

elements are at operator side. Centralised auto

lubrication system.

Centralised auto

lubrication system. Complete PLC

Panel

with high quality wiring and component.

Complete PLC

Panel

with high quality wiring and component. Special cover

protection for machine slides and vice screw.

Special cover

protection for machine slides and vice screw. Machine with

enclosure.

Machine with

enclosure. Operating and

maintenance manual.

Operating and

maintenance manual.

Key Features :

Technical Specifications - ICF Models

| Specification | ICF - 500 | ICF - 1000 |

|---|---|---|

| Maximum Length of Work Piece (Two Vices) | 500 mm | 1000 mm |

| Minimum Length of Work Piece | 100 mm | 100 mm |

| Maximum Dia Admitted in Two Vices | 125 mm | 125 mm |

| Minimum Dia Admitted in Two Vices | 15 mm | 15 mm |

| Maximum Dia Can be Faced (STD, Tool Holder) | 65 mm (Optional - 80 mm) | 65 mm (Optional - 80 mm) |

| Spindle RPM | 750 STD (350, 500, 1000 Optional) | 750 STD (350, 500, 1000 Optional) |

| Spindle Motor LH/RH | 3 HP / 2.2 KW (945 RPM) | 3 HP / 2.2 KW (945 RPM) |

| Maximum Stroke of Each Quill | 50 mm | 50 mm |

| Quill Feed System | 2 Hydraulic cylinders | 2 Hydraulic cylinders |

| Job Clamping System | Hydraulic Motor Driven Screw Clamp | Hydraulic Motor Driven Screw Clamp |

| Center Drill Size | BSSS3 to BSSS6 or as Per ISI STD | BSSS3 to BSSS6 or as Per ISI STD |

| Lubrication | Auto Centralized Lubrication System | Auto Centralized Lubrication System |

| Hydraulic Motor Power | 4.5 HP / 3.3 KW (1440 RPM) | 4.5 HP / 3.3 KW (1440 RPM) |

| Coolant System | Through Spindle (RV 401170 Pump, 0.37 He 3Ph) | Through Spindle (RV 40 / 170 Pump, 0.37 en 3Ph) |

| Total Machine Volume with STD Equipments | Length 2000 x Breadth 1200 x Height 1600 mm | Length 2500 x Breadth 1200 x Height 1600 mm |

| Total Machine Weight | 1760 Kg (1535 Kg Machine + 225 Kg Hyd. System) | 1880 Kg (1655 Kg Machine + 225 Kg Hyd. System) |

| Power Requirement | 11 HP / 8.2 KW | 11 HP / 8.2 KW |

| Machine Colour | White and Grey | White and Grey |

Centering & Facing Machines

The PCT Centering & Facing Machines are high-precision industrial machines designed to enhance the accuracy and efficiency of metalworking processes. These machines are widely used in manufacturing industries where precise centering and facing operations are critical for component quality and performance.

Slotting Machine

The Heavy Duty Slotting Machine model HP/HSM/4 Size 4 is a high-performance, robust slotting machine designed for precision cutting and machining of heavy-duty materials. This slotting machine is engineered to handle a wide range of industrial applications, making it suitable for heavy and complex machining tasks, including metalworking and tool production.

Offers precise

machining, ensuring high accuracy in slotting and

cutting applications. Ideal for producing clean and accurate slots in

various

heavy materials.

Offers precise

machining, ensuring high accuracy in slotting and

cutting applications. Ideal for producing clean and accurate slots in

various

heavy materials.  Built with a

heavy-duty frame and premium components,

this machine is highly durable and can handle intensive use in demanding

environments.

Built with a

heavy-duty frame and premium components,

this machine is highly durable and can handle intensive use in demanding

environments. The

machine’s powerful motor and optimized design allow for

fast and efficient operations, reducing machining time and enhancing

productivity.

The

machine’s powerful motor and optimized design allow for

fast and efficient operations, reducing machining time and enhancing

productivity. Suitable

for diverse materials and slotting requirements,

accommodating different sizes, shapes, and depths with ease.

Suitable

for diverse materials and slotting requirements,

accommodating different sizes, shapes, and depths with ease.

Key Features :

Technical Data

| Parameter | Specification |

|---|---|

| Maximum Stroke | 101 mm (4") |

| Minimum Stroke | 20 mm |

| Maximum Diameter Accommodated | 101 mm (4") |

| Distance Between Table & Head | 560 mm |

| Diameter of Table | 270 mm |

| Longitudinal Traverse of Table | 220 mm |

| Transverse Traverse of Table | 180 mm |

| Overall Height | 950 mm |

| Length of Bed | 610 mm |

| Width of Bed | 270 mm |

| Height of Bed | 250 mm |

| Height of Head | 510 mm |

| Face of Head Dimensions | 280 x 190 mm |

| Number of Speeds | 2 |

| Ram Cycle per Minute | 48, 58 |

| Electric Motor Required | 1 HP, 960 RPM |

| 'V' Belt Required | Size: A-60, Quantity: 2 |

| Net Weight (Approx) | 360 kg |

Slotting Machine

The Heavy Duty Slotting Machine HP/HSM/4 Size 8 is a powerful, high-capacity slotting machine designed to handle the demands of industrial-grade slotting and cutting tasks. Engineered to provide exceptional strength and precision, the Size 8 model is suitable for heavy-duty applications in industries such as automotive, aerospace, metalworking, and heavy machinery.

The Size 8 model

offers a larger cutting range, enabling it

to handle bigger and more complex materials, making it suitable for projects

that

require deep slots or cuts.

The Size 8 model

offers a larger cutting range, enabling it

to handle bigger and more complex materials, making it suitable for projects

that

require deep slots or cuts. Designed for

high-precision slotting, it ensures

clean, accurate cuts, even with larger workpieces. Its stable frame

minimizes

vibration and movement during operation, contributing to precise and

consistent

results.

Designed for

high-precision slotting, it ensures

clean, accurate cuts, even with larger workpieces. Its stable frame

minimizes

vibration and movement during operation, contributing to precise and

consistent

results. With a more

powerful

motor than smaller models, the

HP/HSM/4 Size 8 can manage intensive tasks with ease, reducing operational

time

while increasing efficiency in high-demand environments.

With a more

powerful

motor than smaller models, the

HP/HSM/4 Size 8 can manage intensive tasks with ease, reducing operational

time

while increasing efficiency in high-demand environments.

Key Features :

Technical Data

| Parameter | Specification |

|---|---|

| Model | HP/HSM/7 Size 7" (180 mm) |

| Stroke Maximum | 180 mm (7") |

| Stroke Minimum | 20 mm |

| Maximum Diameter Accommodated | 600 mm |

| Distance between Table & Head | 325 mm |

| Diameter of Table | 270 mm |

| Traverse of Table Longitudinal | 245 mm |

| Traverse of Table Transverse | 180 mm |

| Height Overall | 1180 mm |

| Length of Bed | 680 mm |

| Width of Bed | 275 mm |

| Height of Bed | 280 mm |

| Height of Head | 715 mm |

| Face of Head | 350x195 mm |

| Number of Speeds | 2 |

| Ram Cycles Per Minute | 48, 58 |

| Electric Motor Required (HP) | 1 |

| Motor Speed (RPM) | 960 |

| V-Belt Size | A-62 (2 belts) |

| Net Weight (Approx) | 400 Kg |

Slotting Machine

The Heavy Duty Slotting Machine HP/HSM/4 Size 7 is a robust, mid-to-large capacity slotting machine engineered for high-precision, heavy-duty applications across a variety of industries. Built with a focus on versatility, accuracy, and durability, the Size 7 model is ideal for manufacturing processes that require both power and control in slotting and cutting tasks.

Equipped with a

highly accurate control system, the Size 7

machine provides consistent slotting quality, ensuring precision with

minimal

deviations across large or complex workpieces.

Equipped with a

highly accurate control system, the Size 7

machine provides consistent slotting quality, ensuring precision with

minimal

deviations across large or complex workpieces. Designed with a

strong motor, the HP/HSM/4 Size 7 combines

power with operational speed, making it well-suited for high-output

environments

and

reducing processing time..

Designed with a

strong motor, the HP/HSM/4 Size 7 combines

power with operational speed, making it well-suited for high-output

environments

and

reducing processing time.. The machine’s

sturdy

frame and high-quality components withstand

extensive use, handling heavy materials and demanding jobs without

compromising

performance.

The machine’s

sturdy

frame and high-quality components withstand

extensive use, handling heavy materials and demanding jobs without

compromising

performance.

Key Features :

Technical Data

| Parameter | Specification |

|---|---|

| Model | HP/HSM/ Size 8" (203 mm) |

| Stroke Maximum | 203 mm (8") |

| Stroke Minimum | 20 mm |

| Maximum Diameter Accommodated | 650 mm |

| Distance between Table & Head | 325 mm |

| Diameter of Table | 355 mm |

| Traverse of Table Longitudinal | 300 mm |

| Traverse of Table Transverse | 235 mm |

| Height Overall | 1350 mm |

| Length of Bed | 860 mm |

| Width of Bed | 320 mm |

| Height of Bed | 320 mm |

| Height of Head | 820 mm |

| Face of Head | 421x215 mm |

| Number of Speeds | 2 |

| Ram Cycles Per Minute | 45, 55 |

| Electric Motor Required (HP) | 1.5 |

| Motor Speed (RPM) | 1440 |

| V-Belt Size | B-65, B-60 (2+2 belts) |

| Net Weight (Approx) | 700 Kg |

Slotting Machine

The Heavy Duty Slotting Machine HP/HSM/10 is engineered for industrial-level slotting, ideal for large-scale, precise, and high-capacity machining tasks. Known for its robust construction and high-power capabilities, this machine is designed for challenging applications across sectors such as automotive, aerospace, heavy equipment manufacturing, and metal fabrication.

Designed to

accommodate larger workpieces and more extensive

slotting requirements, the HP/HSM/10 handles deep, wide cuts with ease.

Designed to

accommodate larger workpieces and more extensive

slotting requirements, the HP/HSM/10 handles deep, wide cuts with ease. A powerful motor

enables it to tackle tough

materials, like hardened steel and alloys, while maintaining efficient

operation

for

improved productivity.

A powerful motor

enables it to tackle tough

materials, like hardened steel and alloys, while maintaining efficient

operation

for

improved productivity. Equipped with a

high-precision control system, it

ensures consistent, accurate slotting across even the most demanding jobs,

minimizing waste and ensuring top-quality results.

Equipped with a

high-precision control system, it

ensures consistent, accurate slotting across even the most demanding jobs,

minimizing waste and ensuring top-quality results.

Key Features :

Technical Data

| Parameter | Specification |

|---|---|

| Model | HP/HSM/10 Size 10" (250 mm) |

| Stroke Maximum | 250 mm (10") |

| Stroke Minimum | 20 mm |

| Maximum Diameter Accommodated | 720 mm |

| Distance between Table & Head | 360 mm |

| Diameter of Table | 355 mm |

| Traverse of Table Longitudinal | 400 mm |

| Traverse of Table Transverse | 235 mm |

| Height Overall | 1450 mm |

| Length of Bed | 970 mm |

| Width of Bed | 320 mm |

| Height of Bed | 340 mm |

| Height of Head | 920 mm |

| Face of Head | 445x250 mm |

| Number of Speeds | 3 |

| Ram Cycles Per Minute | 42, 52, 62 |

| Electric Motor Required (HP) | 2 |

| Motor Speed (RPM) | 1440 |

| V-Belt Size | B-68, B-72 (2+2 belts) |

| Net Weight (Approx) | 900 Kg |

Slotting Machine

The Heavy Duty Slotting Machine HP/HSM/12 is a top-of-the-line slotting machine crafted for the most demanding industrial applications, where precision, power, and capacity are critical. Engineered for durability and equipped with advanced features, this model is designed to handle heavy-duty slotting in large workpieces, ideal for sectors such as automotive, aerospace, shipbuilding, and heavy equipment manufacturing.

The HP/HSM/12

offers

an expansive range, capable of

creating deep and wide slots on large and dense materials, accommodating

highly

specialized industrial requirements.

The HP/HSM/12

offers

an expansive range, capable of

creating deep and wide slots on large and dense materials, accommodating

highly

specialized industrial requirements. With a highly

powerful motor, this model efficiently handles tough

materials, including hardened steels and alloys, delivering smooth cuts and

reducing

slotting time significantly.

With a highly

powerful motor, this model efficiently handles tough

materials, including hardened steels and alloys, delivering smooth cuts and

reducing

slotting time significantly. The machine’s

advanced control system ensures pinpoint

accuracy, providing uniform and consistent cuts even with heavy loads,

crucial

for

high-spec manufacturing.

The machine’s

advanced control system ensures pinpoint

accuracy, providing uniform and consistent cuts even with heavy loads,

crucial

for

high-spec manufacturing.

Key Features :

Technical Data

| Parameter | Specification |

|---|---|

| Model | HP/HSM/12 Size 12" (305 mm) |

| Stroke Maximum | 305 mm (12") |

| Stroke Minimum | 25 mm |

| Maximum Diameter Accommodated | 900 mm |

| Distance between Table & Head | 460 mm |

| Diameter of Table | 425 mm |

| Traverse of Table Longitudinal | 700 mm |

| Traverse of Table Transverse | 360 mm |

| Height Overall | 1670 mm |

| Length of Bed | 1370 mm |

| Width of Bed | 355 mm |

| Height of Bed | 390 mm |

| Height of Head | 1010 mm |

| Face of Head | 530x340 mm |

| Number of Speeds | 3 |

| Ram Cycles Per Minute | 26, 36, 46 |

| Electric Motor Required (HP) | 2 |

| Motor Speed (RPM) | 1440 |

| V-Belt Size | B-80 (2+2 belts) |

| Net Weight (Approx) | 1400 Kg |

Slotting Machine

The Heavy Duty Slotting Machine HP/HSM/16 is a high-capacity industrial machine designed for the most rigorous slotting and machining applications. With its robust construction and advanced features, this model is optimized for high-performance operations in demanding industries such as aerospace, automotive, heavy machinery manufacturing, and metal fabrication.

The HP/HSM/16 is

designed to handle large workpieces,

making it capable of producing deep and wide slots required for heavy-duty

applications, while maintaining high precision.

The HP/HSM/16 is

designed to handle large workpieces,

making it capable of producing deep and wide slots required for heavy-duty

applications, while maintaining high precision. Featuring a

high-performance motor, this machine

efficiently processes tough materials such as hardened steel, titanium, and

other

dense alloys, ensuring optimal cutting speed and efficiency.

Featuring a

high-performance motor, this machine

efficiently processes tough materials such as hardened steel, titanium, and

other

dense alloys, ensuring optimal cutting speed and efficiency. Equipped with

advanced control technology, the HP/HSM/16

delivers accurate slotting with minimal tolerance deviations, ensuring

consistent

quality across all operations and reducing waste.

Equipped with

advanced control technology, the HP/HSM/16

delivers accurate slotting with minimal tolerance deviations, ensuring

consistent

quality across all operations and reducing waste.

Key Features :

Technical Data

| Parameter | Specification |

|---|---|

| Model | HP/HSM/16 Size 16" (405 mm) |

| Stroke Maximum | 405 mm (16") |

| Stroke Minimum | 20 mm |

| Maximum Diameter Accommodated | 1400 mm |

| Distance between Table & Head | 600 mm |

| Diameter of Table | 520 mm |

| Traverse of Table Longitudinal | 900 mm |

| Traverse of Table Transverse | 425 mm |

| Height Overall | 2300 mm |

| Length of Bed | 1480 mm |

| Width of Bed | 410 mm |

| Height of Bed | 425 mm |

| Height of Head | 1550 mm |

| Face of Head | 610 x 360 mm |

| Number of Speeds | 3 |

| Ram Cycles Per Minute | 35, 45, 55 |

| Electric Motor Required (HP) | 3 |

| Motor Speed (RPM) | 1440 |

| V-Belt Size | B-85 (2+2 belts) |

| Net Weight (Approx) | 1850 Kg |

High Speed Circular Saw Machine

The High Speed Circular Saw Machine CS 80 is a precision-engineered cutting solution designed for high-speed and accurate metal cutting applications. This machine offers superior efficiency, durability, and precision, making it ideal for industries requiring rapid and precise cutting operations.

Double Column Automatic Band Saw Machine

The Double Column Automatic Band Saw Machine DCM 650 is a highly efficient and precision-engineered cutting solution designed for high-capacity metal cutting applications. With its double-column structure, this machine ensures superior stability and accuracy, making it ideal for industrial environments requiring high-performance cutting operations.

Double Column Automatic Band Saw Machine

The Double Column Automatic Band Saw Machine DCA 260 is a powerful and precise cutting solution tailored for industrial applications requiring high-speed and accurate metal cutting. Designed for efficiency and reliability, this machine is ideal for industries that demand heavy-duty cutting capabilities.